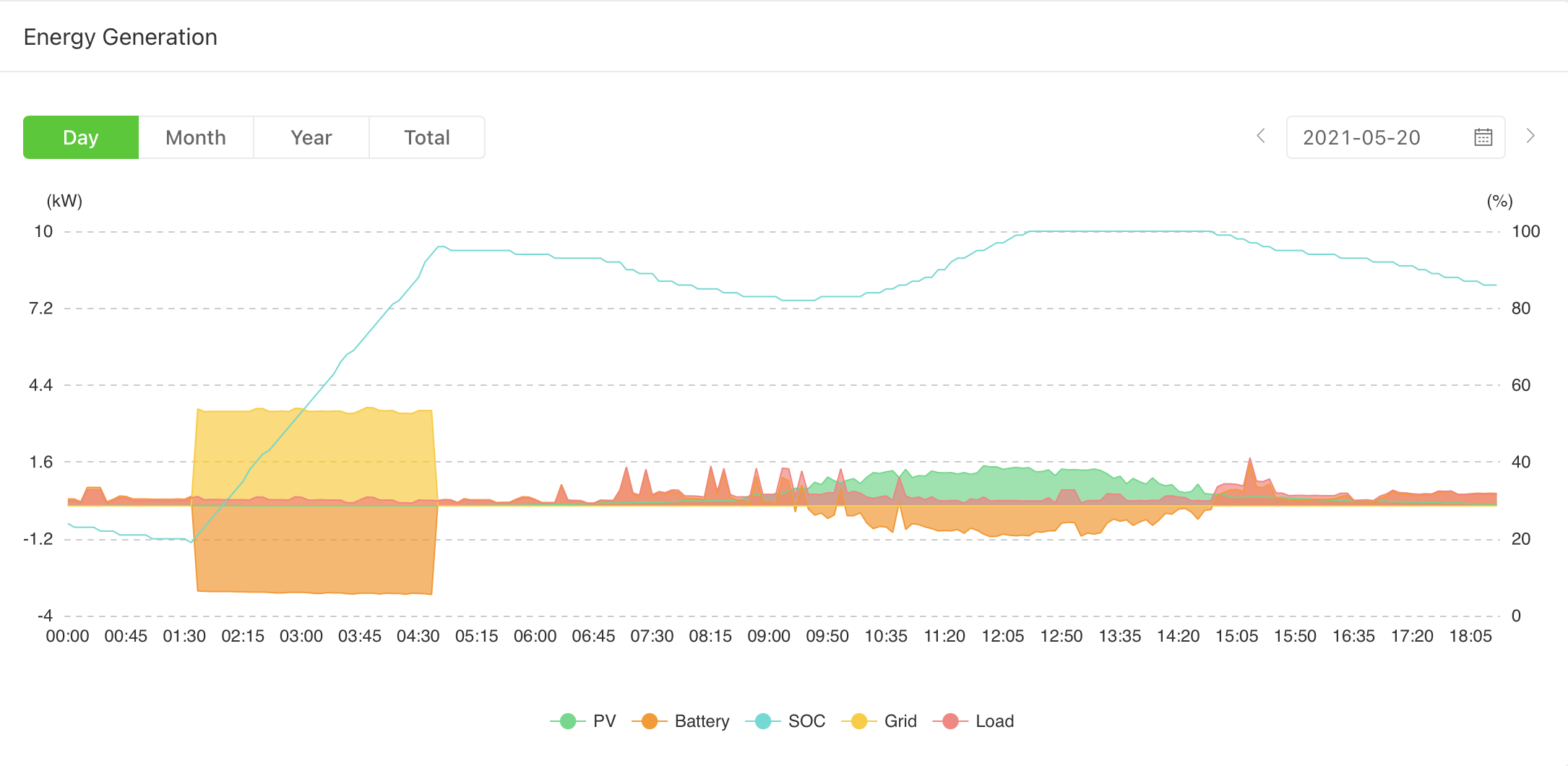

This switch and lightboard replaces the old Xantrex dashboard in my house here at the Kupreanof Yacht Club. All the detailed information is now on my computer….. On the wall in my house there are three lights–like a stoplight: green, yellow and red. These tell me what is running 150′ away in the well-house where all the energy meets. Green = Generator is running; Yellow = Batteries are full and the excess energy is being dumped into my Tulikivi; and Red = is the “emergency brake” adding resistance to the turbine–in essence, the main Tulikivi heater has failed and the MidNite Clipper has stepped in. All these details are also on my computer and my iPhone in a slick graphic:

Above is an 18 hour graph of energy distribution. The tan/orange block is a 3:15 hour charging cycle by the generator beginning at 1:30am. The first spike is the morning coffee-pot and then the sun comes out (barely) which is shown in green (and orange below is the absorption into the batteries. The light green line is the State of Charge (SOC) of the batteries, building during the charge cycle and decaying during periods of loads. The hydro/creek is not flowing.

Let’s start at the top of the hill for review:

This is the East Intake screen–looking downstream during a dry spell. I’ve yet to move rocks to encourage water to flow over the spillway.

This is the East Intake screen–looking downstream during a dry spell. I’ve yet to move rocks to encourage water to flow over the spillway.

Update: Here I’ve created a boulder ramp up to the lip of the intake. Fish can easily navigate the 14″ into the pond above. I’ll let sedimentation fill in and revisit next flood cycle:

Here’s the screen looking back upstream–there is quite a pond just above. These are designed by Robert Weir (perfect name for this business), Hyroscreen Co. LLC. This screen is 36″ wide and built of stainless steel. With the West Intake, I’ve 60″ of stream width.

Here’s the screen looking back upstream–there is quite a pond just above. These are designed by Robert Weir (perfect name for this business), Hyroscreen Co. LLC. This screen is 36″ wide and built of stainless steel. With the West Intake, I’ve 60″ of stream width.

This is the West Intake as installed. The west arm of my creek is only about 25% of the total flow. I chose to have two intakes to allow the penstock (piping) to escape the stream channel. Fifty feet below, at the confluence, I’m in a “canyon” and would have run in the creek bed which would be vulnerable to high flow damage, logs, etc. . By putting the intakes uphill a bit, I can capture the meadow at the confluence and also gain about 3 more feet of head pressure. The slope here is only 1″ in 10′ but only for 50′ of the 458′ total run. The total length of the penstock is 458′ with 28′ of head pressure; about a half inch drop per foot of run. When it rains…..

This is the West Intake as installed. The west arm of my creek is only about 25% of the total flow. I chose to have two intakes to allow the penstock (piping) to escape the stream channel. Fifty feet below, at the confluence, I’m in a “canyon” and would have run in the creek bed which would be vulnerable to high flow damage, logs, etc. . By putting the intakes uphill a bit, I can capture the meadow at the confluence and also gain about 3 more feet of head pressure. The slope here is only 1″ in 10′ but only for 50′ of the 458′ total run. The total length of the penstock is 458′ with 28′ of head pressure; about a half inch drop per foot of run. When it rains…..

…..the stream fills rapidly. This screen is a 24″ wide with a 6″ pipe which alone will fill the penstock. I’m aiming for harvesting water in lower flow situations which is a lot of the time. Recall that this is a high volume/low head application–in this case 28′ of head pressure or 12 lbs. at the turbine. The Penstock will move 340 gallons/minute ideally. Friction is the enemy.

…..the stream fills rapidly. This screen is a 24″ wide with a 6″ pipe which alone will fill the penstock. I’m aiming for harvesting water in lower flow situations which is a lot of the time. Recall that this is a high volume/low head application–in this case 28′ of head pressure or 12 lbs. at the turbine. The Penstock will move 340 gallons/minute ideally. Friction is the enemy.

The two intakes converge about 50′ down where I installed a “resilient wedge” style gate valve. This valve will remain open unless I’m working on the turbine below. All fittings are dry-fit above the valve as pressure is low. By lifting the left (East) “elbow” of pipe, I can uncouple the system and make repairs/modifications.

The two intakes converge about 50′ down where I installed a “resilient wedge” style gate valve. This valve will remain open unless I’m working on the turbine below. All fittings are dry-fit above the valve as pressure is low. By lifting the left (East) “elbow” of pipe, I can uncouple the system and make repairs/modifications.

This photo is downhill about 100′ where it crosses the stream. Supports are Alaska Yellow Cedar 2 X 4s which are adequate but will require augmenting a bit. I’ve installed one 45° and one 22.5° elbow here to make this bend.

This photo is downhill about 100′ where it crosses the stream. Supports are Alaska Yellow Cedar 2 X 4s which are adequate but will require augmenting a bit. I’ve installed one 45° and one 22.5° elbow here to make this bend.

This is the final 100′ before entering the powerhouse–this is a natural bend in the pipe–there are only three angled couplings: the two just mentioned and one 45° in the East arm. I’m excluding the two 90° bends at the Intakes–the higher in the system, the less frictional losses. This last run at the lowest end of the penstock is perfect–no sharp bends. Still some support-work to do here but nothing is moving.

This is the final 100′ before entering the powerhouse–this is a natural bend in the pipe–there are only three angled couplings: the two just mentioned and one 45° in the East arm. I’m excluding the two 90° bends at the Intakes–the higher in the system, the less frictional losses. This last run at the lowest end of the penstock is perfect–no sharp bends. Still some support-work to do here but nothing is moving.

Final approach to the powerhouse with an identical valve. This valve will be used to throttle down volume to build up head pressure (back up water up the penstock) at lower flowrates–and will take some trial and error. The turbine’s top speed is about 1100 rpm and it takes only 300 rpm or so to float the batteries during light loads–all this will take some trial & error experimentation.

Final approach to the powerhouse with an identical valve. This valve will be used to throttle down volume to build up head pressure (back up water up the penstock) at lower flowrates–and will take some trial and error. The turbine’s top speed is about 1100 rpm and it takes only 300 rpm or so to float the batteries during light loads–all this will take some trial & error experimentation.

I would be remiss if I didn’t mention Bill Scott’s (Scott Hydroelectric) turbine. “Saint Bill” has spent hours on the phone with me and has built many hundreds of these which can be found around the planet; principally in Africa. Powder coated cast aluminum casing, stainless steel internal parts and totally rebuildable in the field. My turbine proudly boasts a brass plaque with #191 on it. Good job Bill!

I would be remiss if I didn’t mention Bill Scott’s (Scott Hydroelectric) turbine. “Saint Bill” has spent hours on the phone with me and has built many hundreds of these which can be found around the planet; principally in Africa. Powder coated cast aluminum casing, stainless steel internal parts and totally rebuildable in the field. My turbine proudly boasts a brass plaque with #191 on it. Good job Bill!

Four hundred and fifty feet distant is the well house (to my back here). The wire (UF-B#6-3 strand with ground) runs underground, then under the gazebo and under the boardwalk. I utilize an old drainage ditch from the well house overflow (never have seen it overflow) and up the drain-pipe to the MidNite Clipper. I’ve found an internet company, Wire & Cable Your Way that ships just about any type of wire immediately, and for a good price. Their tech support is also very good and will walk you through the process or help you determine which wire is best for projects like this.

Four hundred and fifty feet distant is the well house (to my back here). The wire (UF-B#6-3 strand with ground) runs underground, then under the gazebo and under the boardwalk. I utilize an old drainage ditch from the well house overflow (never have seen it overflow) and up the drain-pipe to the MidNite Clipper. I’ve found an internet company, Wire & Cable Your Way that ships just about any type of wire immediately, and for a good price. Their tech support is also very good and will walk you through the process or help you determine which wire is best for projects like this.

About…..face…..! The last 25′–and the well house. All house power & communication wiring is under this boardwalk but the hydro input comes in from the right in that ditch.

So, now that we’re here in the well house, let’s talk electricity. This is the old battery bank of Chinese manufactured Nickel Iron (NiFe) “Edison” batteries (Hangchong 400 Ah). Goodyear owned the patent until 1970 and all “Edison” style batteries are now produced in China. I am no fan of these as I’ve had 14 failures (out of 40 purchases–I’ve lost count). I got 7 years of use out of these but they cost $16,000 and were advertised as “the last battery you’ll ever buy.” Don’t buy these! They are very high maintenance and I ended up spending more on distilled water than on diesel fuel. If you use rainwater, they void the warranty.

So, now that we’re here in the well house, let’s talk electricity. This is the old battery bank of Chinese manufactured Nickel Iron (NiFe) “Edison” batteries (Hangchong 400 Ah). Goodyear owned the patent until 1970 and all “Edison” style batteries are now produced in China. I am no fan of these as I’ve had 14 failures (out of 40 purchases–I’ve lost count). I got 7 years of use out of these but they cost $16,000 and were advertised as “the last battery you’ll ever buy.” Don’t buy these! They are very high maintenance and I ended up spending more on distilled water than on diesel fuel. If you use rainwater, they void the warranty.

This was an autopsy after I rinsed it out and tried to dry it out–on the recommendation of the dealer “Be Utility Free.” A google search of this company will bring up all sorts of nefarious posts which I will leave to the inquisitive reader–don’t neglect the Better Business Bureau in Colorado either, where I’ve filed a complaint.

This was an autopsy after I rinsed it out and tried to dry it out–on the recommendation of the dealer “Be Utility Free.” A google search of this company will bring up all sorts of nefarious posts which I will leave to the inquisitive reader–don’t neglect the Better Business Bureau in Colorado either, where I’ve filed a complaint.  These are the replacements–Lithium-Iron-Phosphate (LiFePO4)–albeit 260 AmpHours instead of the 400 for the NiFe’s. The advantage here is that these charge quicker so my daily average run-time is now about 2-1/2 hours in stead of the 3.25 hours. They also have a small footprint. These are sealed and are warrantied for 12,000 cycles, which is more cycles than I’ve got left. They are manufactured in Canada by Discover. These batteries also talk to the inverter and to each other–note all the com-wires; i.e. are “closed loop.” They have their own Battery Management Systems. I was dumping 25 gallons into the old NiFe bank about twice a year or so–not these–they are maintenance free except for a firmware update.

These are the replacements–Lithium-Iron-Phosphate (LiFePO4)–albeit 260 AmpHours instead of the 400 for the NiFe’s. The advantage here is that these charge quicker so my daily average run-time is now about 2-1/2 hours in stead of the 3.25 hours. They also have a small footprint. These are sealed and are warrantied for 12,000 cycles, which is more cycles than I’ve got left. They are manufactured in Canada by Discover. These batteries also talk to the inverter and to each other–note all the com-wires; i.e. are “closed loop.” They have their own Battery Management Systems. I was dumping 25 gallons into the old NiFe bank about twice a year or so–not these–they are maintenance free except for a firmware update.

I’ll mention my solar arrays briefly–12 Kyocera 135W panels which generate 22 VDC-oc at about 8 amps per panel. I had wired these 2 X 6 series/parallel to cut down on the high voltage because the largest capacity charge controller accepts only 250 volts and cold winters produce higher voltages. My plan was to upgrade to a 12KW Sol-Ark which has it’s own high-voltage charge controller allowing me to rewire the PV into one series circuit –over 250VDC–which is more efficient for long runs–in my case about 300′. This will allow me to recycle the Midnite Charge Controller for the hydro…..

I’ll mention my solar arrays briefly–12 Kyocera 135W panels which generate 22 VDC-oc at about 8 amps per panel. I had wired these 2 X 6 series/parallel to cut down on the high voltage because the largest capacity charge controller accepts only 250 volts and cold winters produce higher voltages. My plan was to upgrade to a 12KW Sol-Ark which has it’s own high-voltage charge controller allowing me to rewire the PV into one series circuit –over 250VDC–which is more efficient for long runs–in my case about 300′. This will allow me to recycle the Midnite Charge Controller for the hydro…..

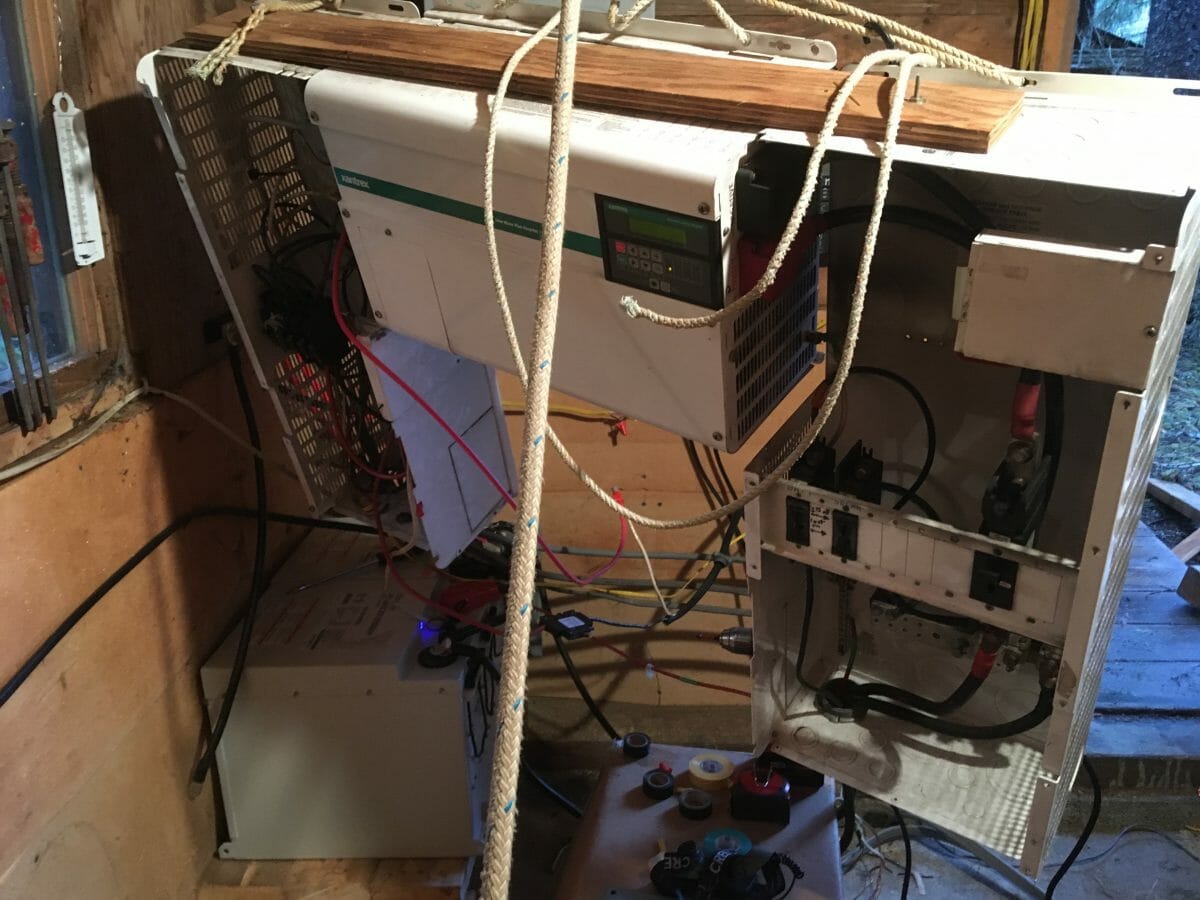

Here is the old Xantrex–a great machine which has served faithfully for 15 years. But it can’t talk to the new batteries only approximate charge rates. The MidNite Charge Controller is the black box on the right sandwiched in. All this would have to be removed from the wall to allow for installation of the new system….but….had to keep producing power as I’m off-grid. Ok, here we go….

Here is the old Xantrex–a great machine which has served faithfully for 15 years. But it can’t talk to the new batteries only approximate charge rates. The MidNite Charge Controller is the black box on the right sandwiched in. All this would have to be removed from the wall to allow for installation of the new system….but….had to keep producing power as I’m off-grid. Ok, here we go….

I first put an anchor on the floor and the ceiling beams–this Xantrex weighs over 150# and is one big magnet. With pullys and heft, I carefully slide it down on skids and let it swing freely mid-air wires still accepting solar, generator and charging to batteries.

I first put an anchor on the floor and the ceiling beams–this Xantrex weighs over 150# and is one big magnet. With pullys and heft, I carefully slide it down on skids and let it swing freely mid-air wires still accepting solar, generator and charging to batteries.

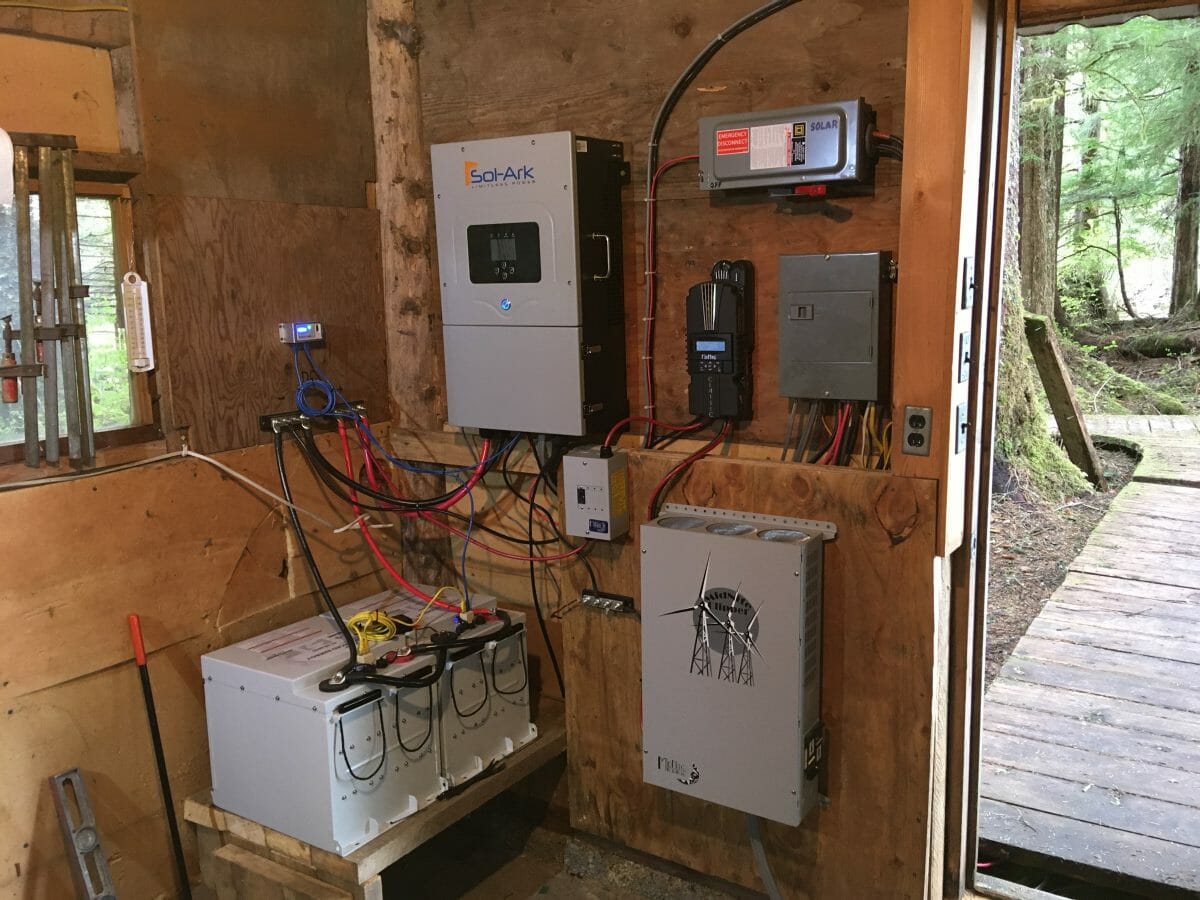

With some minor clean-up, I hang the new Sol-Ark. Their customer service is tops, in fact, better than tops. When I finally went online with it, they noticed an older firmware version and “pushed” the current firmware from their factory back East; all in a few minutes. Now, that’s service. I had earlier looked at Schneider which has taken over Xantrex and before them, Trace, and neither my dealer nor I could get them to answer the phone. Sol-Ark is the new kid on the block and their technology is current (pardon the pun), unlike the competition who have lagged behind. This is 12KW, has a “Smart-Load” feature and is closed loop technology. Totally satisfied!

With some minor clean-up, I hang the new Sol-Ark. Their customer service is tops, in fact, better than tops. When I finally went online with it, they noticed an older firmware version and “pushed” the current firmware from their factory back East; all in a few minutes. Now, that’s service. I had earlier looked at Schneider which has taken over Xantrex and before them, Trace, and neither my dealer nor I could get them to answer the phone. Sol-Ark is the new kid on the block and their technology is current (pardon the pun), unlike the competition who have lagged behind. This is 12KW, has a “Smart-Load” feature and is closed loop technology. Totally satisfied!

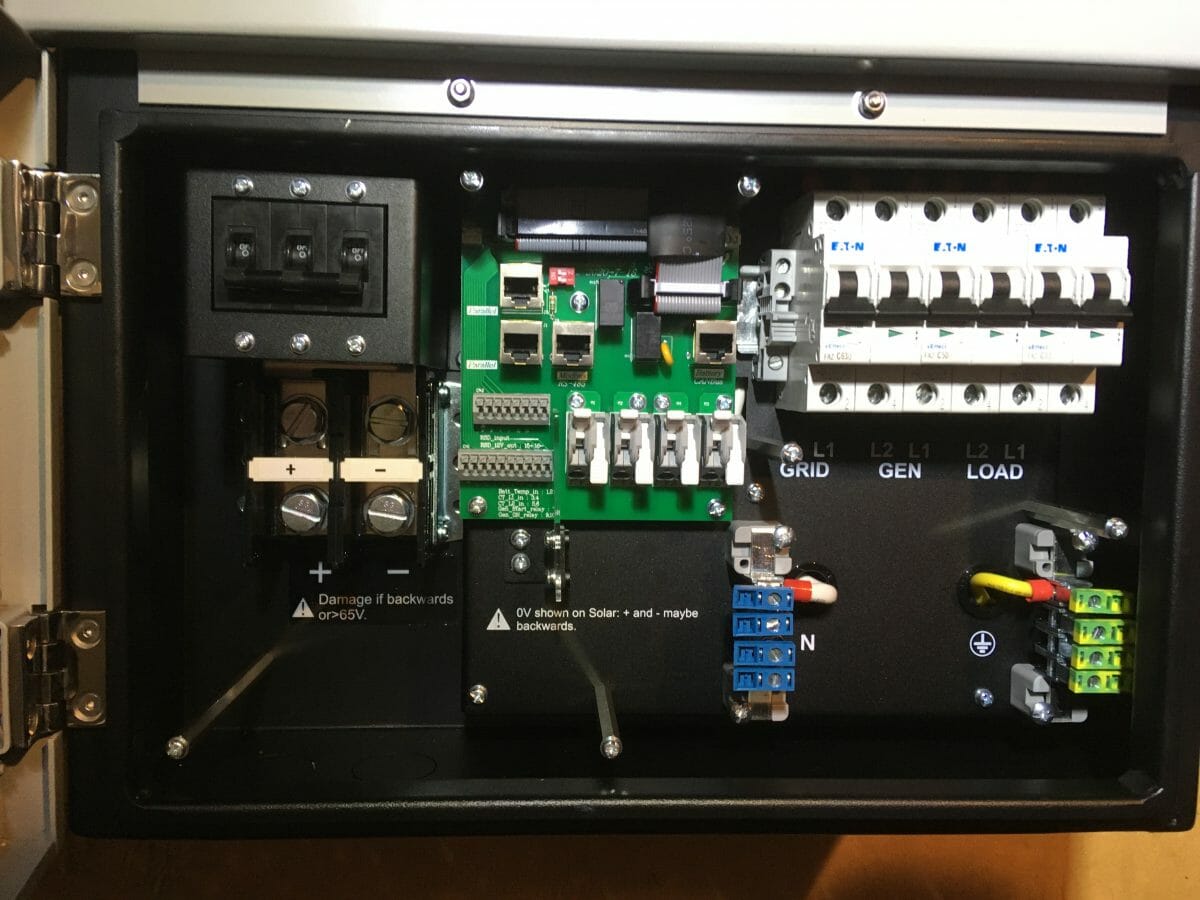

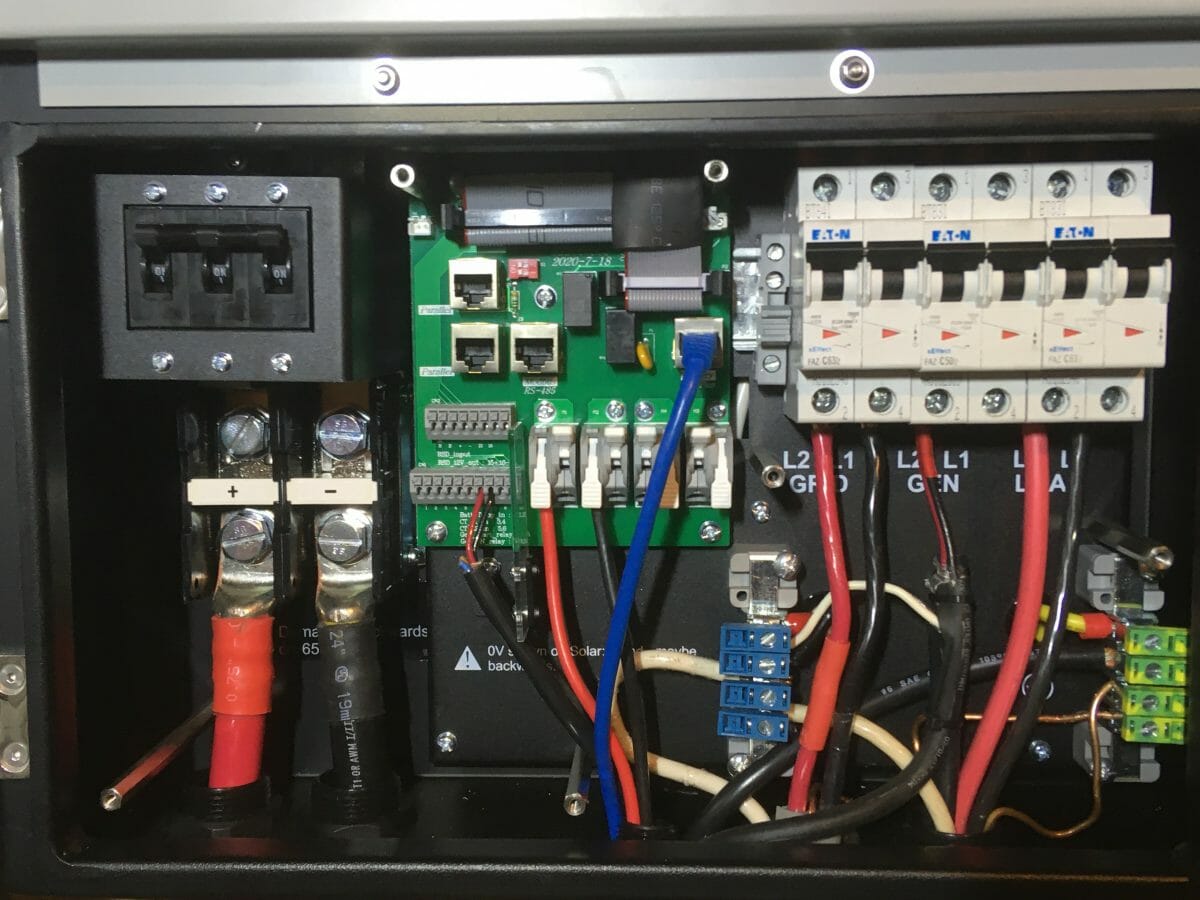

Their wiring design, while very tight, is very understandable and easy to “plug and play.” Battery connections left; Com Ports and Solar Input center (green); Grid/Gen/Load circuits right (white). Blue Neutral and Green Earth Ground lower. The three circuits (Grid, Gen, and Load) are equivalent so being off-grid, I can use the Grid circuit to input the generator. (If you’re grid-tied, you sell power back through this circuit but I’m off-grid so my generator inputs here.) That leaves the Gen Circuit (which is the “Smart Load” feature) available for the dump-load for the hydro. Unlike solar, any turbine must dump excess load into some sort of resistance, in my case, the masonry heater in the house which, while normally wood-fired, is also wired to produce heat. When the batteries top up, the excess power from the hydro ends up here:

Their wiring design, while very tight, is very understandable and easy to “plug and play.” Battery connections left; Com Ports and Solar Input center (green); Grid/Gen/Load circuits right (white). Blue Neutral and Green Earth Ground lower. The three circuits (Grid, Gen, and Load) are equivalent so being off-grid, I can use the Grid circuit to input the generator. (If you’re grid-tied, you sell power back through this circuit but I’m off-grid so my generator inputs here.) That leaves the Gen Circuit (which is the “Smart Load” feature) available for the dump-load for the hydro. Unlike solar, any turbine must dump excess load into some sort of resistance, in my case, the masonry heater in the house which, while normally wood-fired, is also wired to produce heat. When the batteries top up, the excess power from the hydro ends up here:

Here’s the Tulikivi wood heater in action. And here is a previous post during my installation.

Here’s the Tulikivi wood heater in action. And here is a previous post during my installation.

When the batteries are full, these elements (total of 6 in parallel; 3KW at 207VAC). For now, I’ve wired this at 120VAC and if the batteries continue to charge when this is running, the Clipper will intervene as the final dump. Another alternative would be to rewire this to 240VAC, producing more heat in the house. Note: The Sol-Ark requires a 240VAC input from the generator but the output can be either 120 or 240 VAC. Again, this will require some trial & error.

Here’s the finished wiring…..

….minus the CT sensors. The CT sensors provide a feedback loop of charge rates for “peak shaving.” which I’m still a bit foggy on. For now, let’s call it load management. In the Xantrex system, the generator would step in during peak loads so the batteries wouldn’t deplete.

….minus the CT sensors. The CT sensors provide a feedback loop of charge rates for “peak shaving.” which I’m still a bit foggy on. For now, let’s call it load management. In the Xantrex system, the generator would step in during peak loads so the batteries wouldn’t deplete.

And now, for a station break……..what you’ve always been searching for and could never find….until now—Probiotic Prunes! Think of it as Spring Cleaning! I’ll bet they’re gluten free also! So here is the “family pack;” whatever that means……. perhaps everyone can fight for seating order on the throne….. And 10X more effective than yogurt! Buy our Probiotic and Gluten-Free California Prunes! Now, back to our program……

And now, for a station break……..what you’ve always been searching for and could never find….until now—Probiotic Prunes! Think of it as Spring Cleaning! I’ll bet they’re gluten free also! So here is the “family pack;” whatever that means……. perhaps everyone can fight for seating order on the throne….. And 10X more effective than yogurt! Buy our Probiotic and Gluten-Free California Prunes! Now, back to our program……

So, here is the final system wired up. Discover Batteries lower left: “The Batteries that talk to each other.” Like Sol-Ark, they have fantastic technical support. Everything connects to a bus bar directly above. Above the bus, is the Lynk system–light indicating battery state of charge (SOC) that connects via CAT5 to the Sol-Ark, which connects to my WiFi which connects to my iPhone and Mac. I’m wired!

So, here is the final system wired up. Discover Batteries lower left: “The Batteries that talk to each other.” Like Sol-Ark, they have fantastic technical support. Everything connects to a bus bar directly above. Above the bus, is the Lynk system–light indicating battery state of charge (SOC) that connects via CAT5 to the Sol-Ark, which connects to my WiFi which connects to my iPhone and Mac. I’m wired!

I expected our Petersburg Post Office to destroy this and they came pretty close. Ten years ago, they completely destroyed a brand new laptop computer, superglued the case back together, voiding the warranty, then denied the insurance claim…. Our State Representative Don Young stepped into the fray and got me a new computer….but that’s another story that ranks up there with the Mercury engine fiasco…….

I expected our Petersburg Post Office to destroy this and they came pretty close. Ten years ago, they completely destroyed a brand new laptop computer, superglued the case back together, voiding the warranty, then denied the insurance claim…. Our State Representative Don Young stepped into the fray and got me a new computer….but that’s another story that ranks up there with the Mercury engine fiasco…….

But, I digress……back to the wiring……

Solar comes in under the boardwalk (in the photo above), then behind the wire chase near the door, and directly into the horizontal disconnect. It’s important to have this disconnect. From there #10AWG wires lead directly into the Sol-Ark. The hydro comes up an old drain pipe from a ditch outside of the wellhouse–and runs to the powerhouse on the creek all underground. It enters the Midnite Clipper–large gray box on the lower right. Here’s how this works:

The hydro input (3 phase 125VAC) emerges from the floor directly below and goes through a rectifier first. Out comes VDC and through a switch and into a circuitboard that either charges batteries or diverts into the three resisters (2 ohms). If the “Smart-Load” on the Sol-Ark somehow cannot find the dump in the Tulikivi heater, then this will jump in and save the day (and heat my wellhouse).

The hydro input (3 phase 125VAC) emerges from the floor directly below and goes through a rectifier first. Out comes VDC and through a switch and into a circuitboard that either charges batteries or diverts into the three resisters (2 ohms). If the “Smart-Load” on the Sol-Ark somehow cannot find the dump in the Tulikivi heater, then this will jump in and save the day (and heat my wellhouse).

And this begs the question of the red light. These LED bulbs are 20 mA so draw very little current. Now, to see these function in the house 150′ away, I need to pull new wires under the boardwalk and house which I am loathe to do. But…..I have the old com cables from the Xantrex–one holding 25 #26AWG wires–which I can pair up and there are my 6 leads.

You can see the same analog here in the well house lit green, which means the generator is running. But there is a problem….

You can see the same analog here in the well house lit green, which means the generator is running. But there is a problem….

Inductance….. The wires run too close together so they generate current in all three pairs and the LEDs can sense this and away they glow. I then connected the yellow light to the “Smart-Load” and the yellow light turned off, now grounded. But not the red light. But, there was a work-around…… I had two other CAT5 cables that also ran with this 25 lead com cable so I cannibalized each for a light–problem solved! Is “canniblized” non-PC? Just wondering…..

Inductance….. The wires run too close together so they generate current in all three pairs and the LEDs can sense this and away they glow. I then connected the yellow light to the “Smart-Load” and the yellow light turned off, now grounded. But not the red light. But, there was a work-around…… I had two other CAT5 cables that also ran with this 25 lead com cable so I cannibalized each for a light–problem solved! Is “canniblized” non-PC? Just wondering…..

The generator is on, in this case; obvious when you stand in the well house, but not in the house, 150′ distant. And the dump loads are silent. Sol-Ark “Smart-Load’ feature and the MidNite Clipper should add an indicator light to these devices, to indicate that these are in use. The Clipper has no 120VAC–only rectified power that is proportional to the rpm of the turbine, so I need to mull this over. Can an LED light use variable power? A free Ranger Doug Poster to anyone who can wire this up for me….. (I think a relay that could sense any current flow would work).

The generator is on, in this case; obvious when you stand in the well house, but not in the house, 150′ distant. And the dump loads are silent. Sol-Ark “Smart-Load’ feature and the MidNite Clipper should add an indicator light to these devices, to indicate that these are in use. The Clipper has no 120VAC–only rectified power that is proportional to the rpm of the turbine, so I need to mull this over. Can an LED light use variable power? A free Ranger Doug Poster to anyone who can wire this up for me….. (I think a relay that could sense any current flow would work).

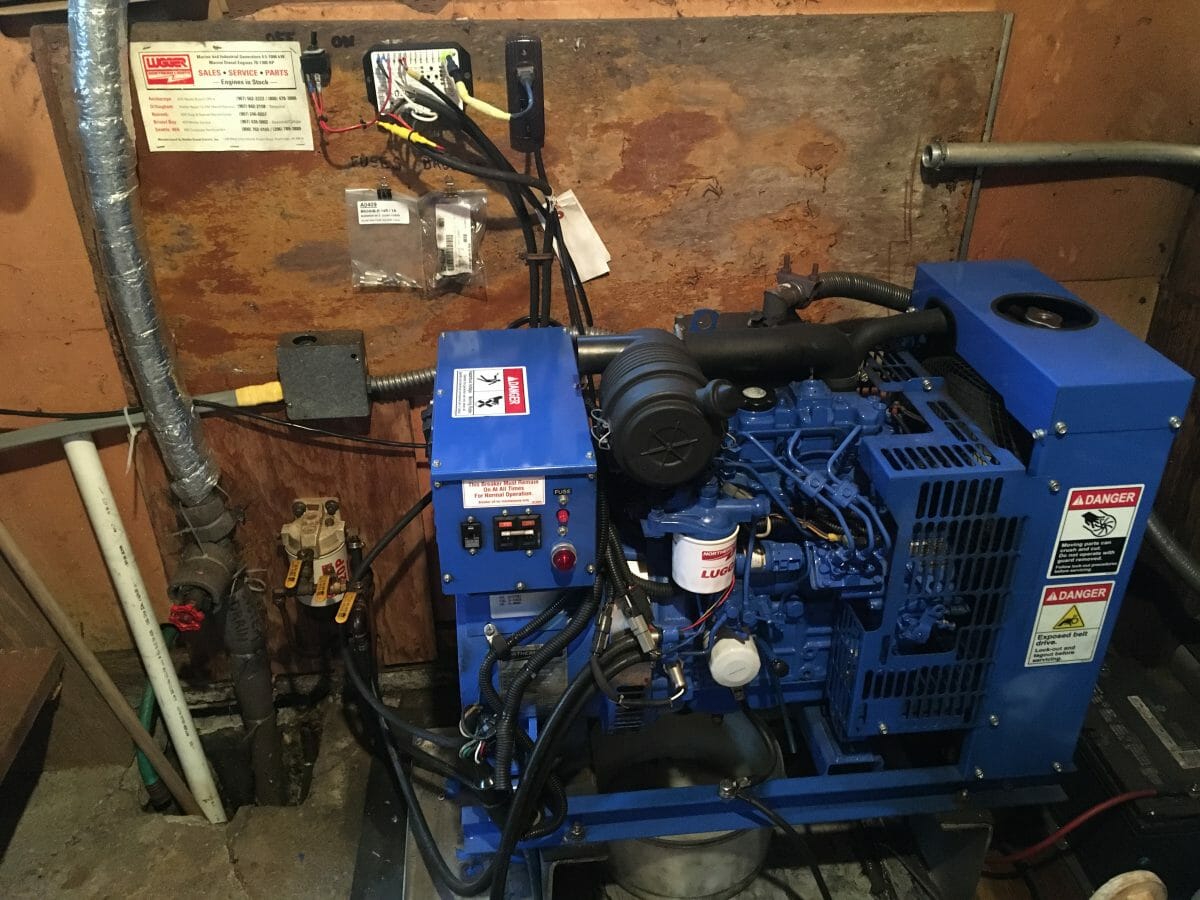

I haven’t mentioned much about the generator/autostart system which the Sol-Ark has to communicate with. The generator is a Northern Light model N-673L 6KW diesel powered. And it’s this diesel that has prompted me to “go green.” And I hate hauling diesel fuel across the Wrangell Narrows. The white box on the upper left is the control which ties to the engine/generator harness on the left of the generator. Diesel generators have pre-heat features which need to be considered when autostarting. Here’s a close-up:

I haven’t mentioned much about the generator/autostart system which the Sol-Ark has to communicate with. The generator is a Northern Light model N-673L 6KW diesel powered. And it’s this diesel that has prompted me to “go green.” And I hate hauling diesel fuel across the Wrangell Narrows. The white box on the upper left is the control which ties to the engine/generator harness on the left of the generator. Diesel generators have pre-heat features which need to be considered when autostarting. Here’s a close-up:

Note the extra fuses and an extra set of brushes for the generator (they wear out about 3000 hours). I also have the customer service phone numbers for Northern Lights–again–a five star rating from the Commodore of the South Kupreanof Yacht Club. Now–the control unit…..I’ve installed a cut-out switch. The two upper right tabs are fully insulated as they’re 120VAC–a feedback loop that tells the Sol-Ark to quit cranking the bendix so it doesn’t wear out; a great improvement over the Xantrex. The plug below this feedback loop is for…….think hard….the green light. This circuit lights up only when the generator is running–a feature that tells the auto-start to quit cranking the starter.

Note the extra fuses and an extra set of brushes for the generator (they wear out about 3000 hours). I also have the customer service phone numbers for Northern Lights–again–a five star rating from the Commodore of the South Kupreanof Yacht Club. Now–the control unit…..I’ve installed a cut-out switch. The two upper right tabs are fully insulated as they’re 120VAC–a feedback loop that tells the Sol-Ark to quit cranking the bendix so it doesn’t wear out; a great improvement over the Xantrex. The plug below this feedback loop is for…….think hard….the green light. This circuit lights up only when the generator is running–a feature that tells the auto-start to quit cranking the starter.

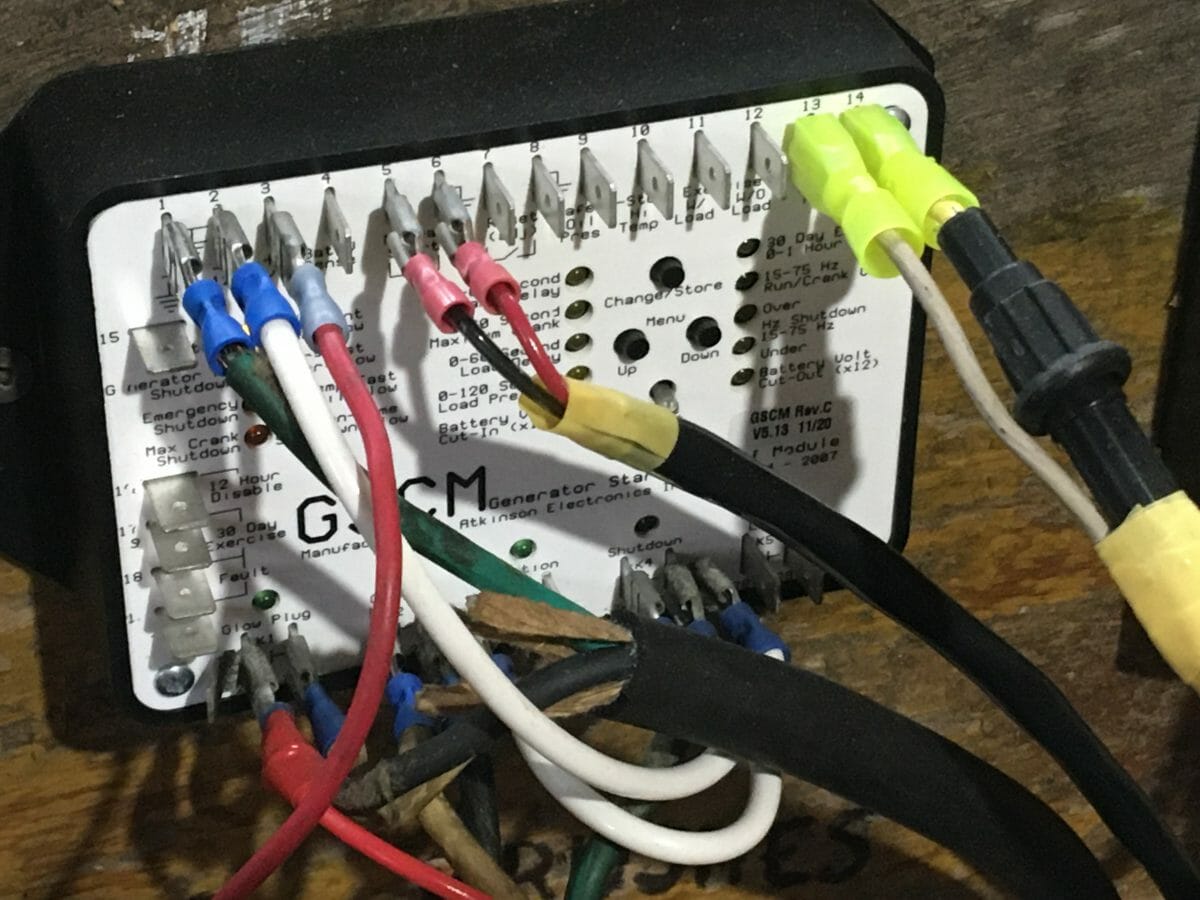

Closer yet. This module is built by Atkinson and is the latest model and specifically designed for my Northern Lights. Their customer service also ranks five star–their techs spend several sessions helping me program this and explained its simplicity.

Closer yet. This module is built by Atkinson and is the latest model and specifically designed for my Northern Lights. Their customer service also ranks five star–their techs spend several sessions helping me program this and explained its simplicity.

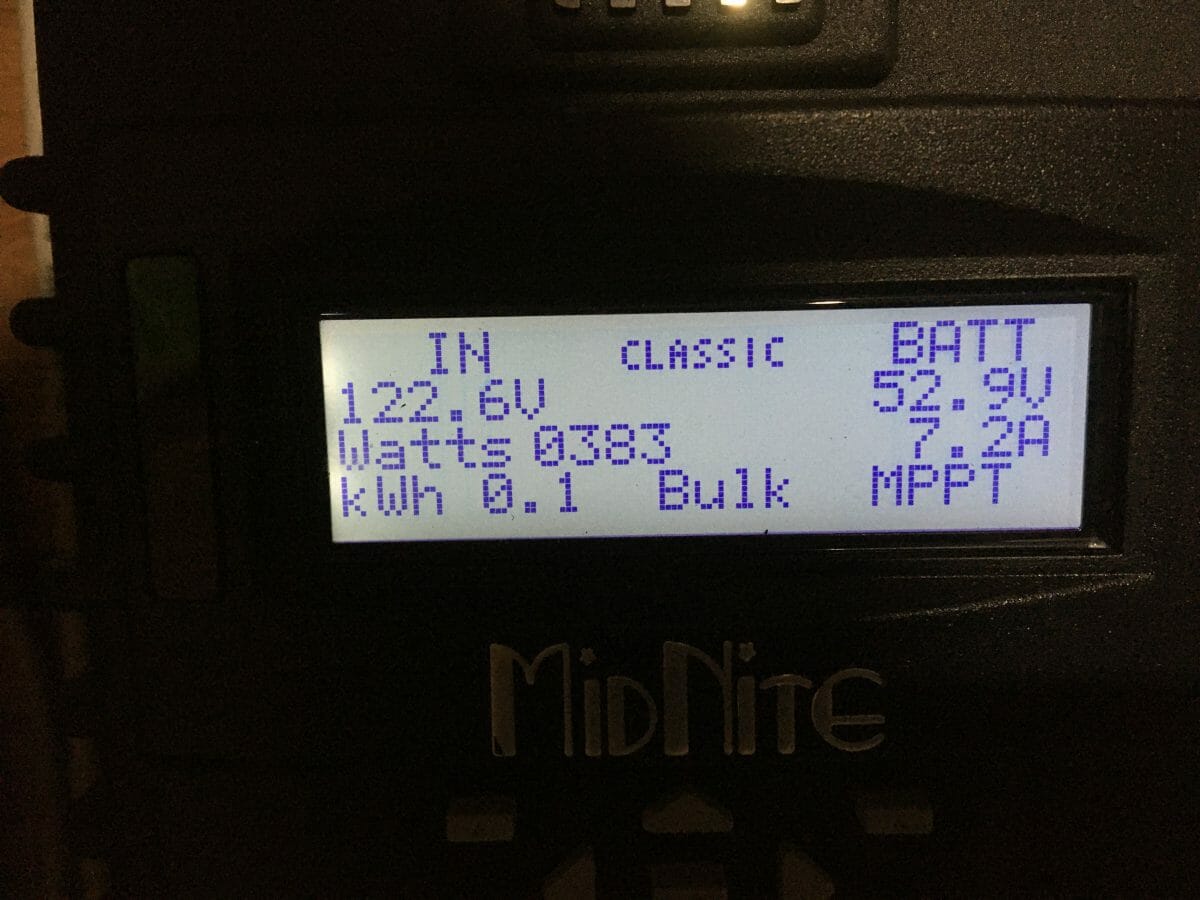

Memorial Day update–I’m online! Rained all night so the penstock filled to capacity but overnight it didn’t turn the turbine because the turbine hadn’t run in almost a year–so I removed the cover and backed up the wheel (it wouldn’t rotate forward for some reason–debris?) several turns and then it took off! I’m averaging about 7.5A right now at 53VDC or about 400W. This is a low value. My usage about matches the charge capacity so my batteries are holding at 67% SOC. Here’s a few photos:

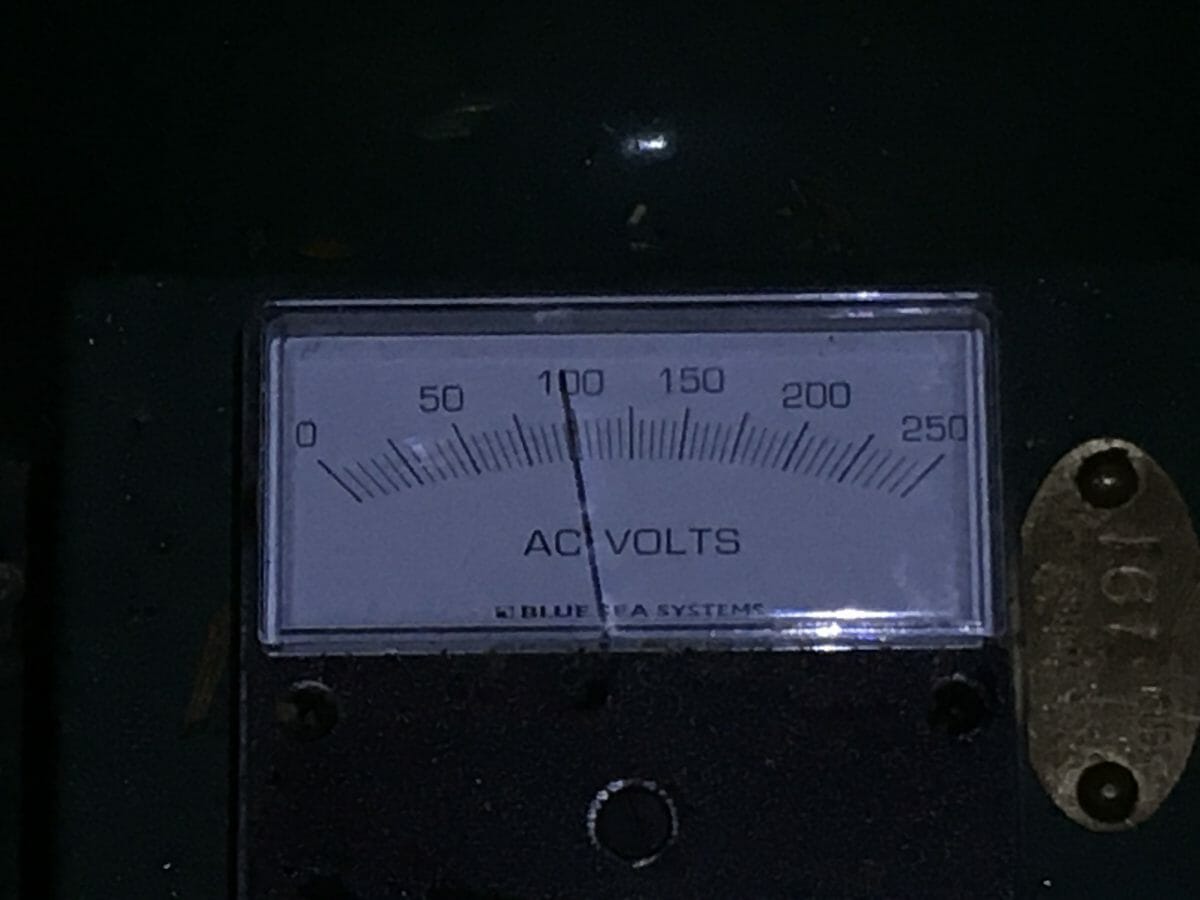

At the turbine (AC three phase current)

At the turbine (AC three phase current)

The powerhouse and raceway. Look at that creek–manna from heaven! For a dynamic movie, click this link: F3EBA6EF-92BF-4908-98CC-AA6B8E71AC81

The powerhouse and raceway. Look at that creek–manna from heaven! For a dynamic movie, click this link: F3EBA6EF-92BF-4908-98CC-AA6B8E71AC81

At the wellhouse–meauring 122VDC at the well-house and 7A into the batteries (I’m drawing about that much with coffee pot, etc. Will the “Smart-Load” work and heat the Tulikivi when the batteries are full? Stay tuned!

All of the well house. Rapunzel, Rapunzel, let down your golden hair. Brothers Grimm.

All of the well house. Rapunzel, Rapunzel, let down your golden hair. Brothers Grimm.

PS: I’m posting this with just one edit so it is available and will add more details later when I learn more about the dump loads, etc. I’ll also share the settings on the Sol-Ark and the MidNite Charge Controller; which will need some trial and error work.

Finally, I must give credit to Northern Arizona Wind & Sun (NAWS); particularly to James and Luis who guided me through all this. James spent hours with me on the phone integrating my hydro into a primarily solar powered system. They also had the best prices in town so if anyone is looking to go solar, call Luis! Their answer time is usually under a minute–so five stars from the Commodore. Thanks NAWS!

PS: I’m driving my 1948 Airstream down to Flagstaff to have them “solar-ize” it next fall. That will be a blog-post to follow!

Here are four earlier posts relevant to this project:

Tulikivi West–Doug’s blog on Tulikivi

Finally, there were many steps backward in this eleven year odyssey. I began with a vague understanding of the methods of harvesting energy from water and am still in a steep learning curve. Solar, I pretty well understand and these systems are mostly geared toward solar, not hydro–but that will change, especially here in Alaska.

A word here about the Scott hydro turbine–Bill Scott, at 81 is still building these. He has placed his hydro turbines all over the world creating power for rural village applications. He should get some sort of Nobel Prize in Engineering methinks. He uses the Morningstar TriStar60 now as his dump load–mainly because it’s very simple and inexpensive for third world applications, compared to the clipper (still under discussion). By upgrading to Sol-Ark, I could recycle my old MidNite Charge Controller to the hydro and the Clipper talks to that better than the TriStar and has the advantage of capturing power before the batteries, not after. It also acts as a turbine brake slowing the rpms in case of a runaway turbine (unloaded is bad).

My greatest frustrations were that all these companies (Morningstar, Discover, Sol-Ark, MidNite, Atkinson, etc.–all excellent products and especially with their customer service), would not talk to each other nor supply any support beyond their own device. It’s a liability thing; but James at NAWS worked through most of these quandaries. In short, I had to assemble the requisite devices myself and test their compatibility. I visited a lot of blogs and realized that every application is unique. I highly recommend Hugh Piggott’s blog. Hugh lives in Scotland and designs and builds his own wind turbines. He’s got more links on his blog than the Oscar Meyer wiener factory.

So a lot of three steps forward–two back and I’m still not done. I’ve two TriStar60 charge controllers and one MidNite 250 for sale! Spare parts now…… Also a functional Xantrex 4048 SW Pro; 29 functional NiFe batteries and lots of other goodies…. which would convert to a perfect 24VDC system.

Of course, the 11 years of permitting is simply unexplainable and unacceptable. Here we have computers and a plethora of government workers that can’t seem to move faster. The paperwork is still unfinished; I’ve final certifications and as-builts to supply to FERC in Portland and annual reports and am subject to inspections. All for a 1.5KW turbine sitting on my private property removing 340 gpm of water 500′ above and returning it 458′ downstream. No wonder we are having such difficulty going green in America. And then there is the greed to profit on oil and the frank ignorance of the electorate. At least I’ve made the step. I will add that Lisa Murkowski’s office (Lane Dixon) contacted me to streamline this paperwork….. Stay tuned! I’m not done yet!!