This is how I first found the Katahdin in 1994–on Orcas island, incarcerated by one of the biggest scoundrels in the Pacific NW and a California transplant to boot. Read my Keel Hauling section for more on this loser. The boat had been sitting for two or three years open to the elements, the compressor cylinder froze and split (I had spares) and was ostensibly there for repairs. But the boatyard thought it more expedient to dismantle the boat and wait for the owner to give up. But I spoiled his plans by purchasing it for $10,000 “as is-where is” out from under his nose and $30,000 worth of lumber also went with the deal…..

Look at this little twit with his captain’s hat–a real Napoleon! He used to walk around with a big calabash pipe in his mouth and a parrot on his shoulder…..no kidding! My marine surveyor stands at the bow.

The first thing I did when I negotiated the purchase of the Katahdin, I hired Phil Shiveley and his Tug Reliable to tow her to Seattle. Not withstanding Mr. Baxter’s objections, Phil and I cut the decklines and she was gone in a flash–liberated and Seattle bound:

What a fresh liberating feeling out in open water. Baxter is licking his wounds and trying to figure out to steal the rest of the lumber–he raised the moorage bill by about $9000 as ransom–but it didn’t work–it’s all posted in Keel Hauling…. It’s an all day trip from Obstruction Pass to Fisherman’s Terminal. Phil did a very professional job and I even have him a nice tip.

What a fresh liberating feeling out in open water. Baxter is licking his wounds and trying to figure out to steal the rest of the lumber–he raised the moorage bill by about $9000 as ransom–but it didn’t work–it’s all posted in Keel Hauling…. It’s an all day trip from Obstruction Pass to Fisherman’s Terminal. Phil did a very professional job and I even have him a nice tip.

I have since on many occasions taken the Katahdin back through Obstruction Pass, parked in front of Baxter’s house and blown my very ample ship’s whistle (it wakes the dead) and then commenced to liberate the contents of my septic system–of course, I wait for a prevailing wind. I encourage others to do the same.

While Phil’s towing the Kat, I’m up on Camano Island gathering much of the engine parts–turns out there are more than I anticipated and my very large rental truck is barely able to handle the load–in fact, the front wheels barely touch the ground. I have to admit, this was a very dangerous trip but I stayed in the slow lane and drove about 45 mph…..

Look at this beauty! Now this is a project–and no project is too big! But to her credit, at this time she was 95 years old and fair as a fiddle and I possessed enough knowledge by now to complete this project–to restore one of the best historic tugs on the coast.

Here she is hauled out and the hull, while showing some wear, is pretty good after all she floated down to Seattle. We replace about 16 planks at this haulout and then transfer to Bakketun & Thomas Boat Yard, right under the Ballard Bridge.

We pull off the shear planks and one more–now only 4″ of freeboard exist! We install about 64 new frame heads mostly in the mid/aft section–where all the water sits. Then, another dozen planks. All the deck beams are also realigned and refastened–they were new but just spanning the beam so the boat didn’t have a lot of seaworthiness.

Here’s a closer look at the frameheads. We also put in a new shelf on this side. Every boat has a worse side–in this case the Katahdin lists to Port and that’s where the water sits.

Note the ‘ceiling’ (inside planks)–they’re 4″ thick here (outer planks are 3″ and the frames are double-sawn 6″ X 12″ for a combined hull thickness of 13″. This is what gives strength to a tug for towing. Most of the aft section had to be replaced–what work that was! The shelf, here just inserted, is the landing for all the deck beams and give the nice shear line of old boats–completely lacking in today’s modern boats.

With the beams bolted into place and the integrity back into the hull, we begin coverboard patterns and begin the decks:

The decks were originally 3″ thick but here we’re reduced to 2″ for economy and she’s not going to see caulk boots or towing again. Each beam here is square with a tapered opening upward for future cotton and cotton caulking sealing with pitch.

This is a work of art! Bakketun and Thomas are crack shipwrights and I would highly recommend them. I would come down every evening after a 10 hour dental practice day and plug holes and vacuum, etc. I put in long hours–for over 6 years. And remember this is my third such vessel.

Here’s the bow section ready to caulk (‘cork’) and…..

….here’s the aft section after caulking with a coat of linseed oil, turpentine and pine tar–a mixture that has been used for thousands of years.

After decks, it’s on to the bulwarks. Originally, the Kat had very accented ‘tumblehome’ which is the bevel inward of these ‘rails.’ The 1899 original bulwarks were actually reversed in this aft section which I think is kind of goofy looking. When barges became the predominant tow, the bulwarks were reversed with ‘tumblehome.’ Here you can see my installation of the Wagner steering system.

Doesn’t she look pretty?

OK–here’s a better angle of the Wagner steering. I used a double ram split apart to economize deck space. Each ram is mounted on a steel strap and spanning the deck beams. This is one skookum setup and has never failed me.

OK–it’s time for a party. Dan Grinstead, seated here on the piano bench talking to the tuba player hauled his piano over to the shipyard for the show–nothing is too heavy for these boys. Dan built the current Washington engine in place in 1982 or 3 and again helped me out with the upper end in 2000. He’s one of the best old diesel mechanics on the block. Well, it’s back to work….

Here’s the completed interior with the new horn timber and ceiling in place…..and all painted pretty….

….and the stem, ready for ballast and flooring to be placed.

We continue to the Texas Deck which is almost completely rebuilt including combings for the pilot house.

The fidley is raised using the headstay–a carefully engineered project. All the piping goes with it and must align again when it’s lowered onto the new roof.

Here’s a closer detail with new galley roof beams. We pretty much blocked this solid to hold the old style steam stack with weighed (literally) a ton. I found some beautiful yellow cedar which I had milled up, then prevarnished it–it is still beautiful 10 years later.

The galley got a new floor and cabinets–pretty much gutted it entirely. It’s the center of the boat although my engineer buddies will argue for the engine room.

Next I build all new doors–clear Doug Fir and varnished with some guchi crap from Florida that failed within two years. Cetol is the only product I’ll use today. The top two pilothouse doors are still clean after 10 winters in Alaska and that goes for the decks and cap rails. Varnish is for fools.

Seems there were leaks everywhere and the pilothouse is no exception. All rebuilt and rewired. I sport the same electronics as the Alaska Ferries and love it.

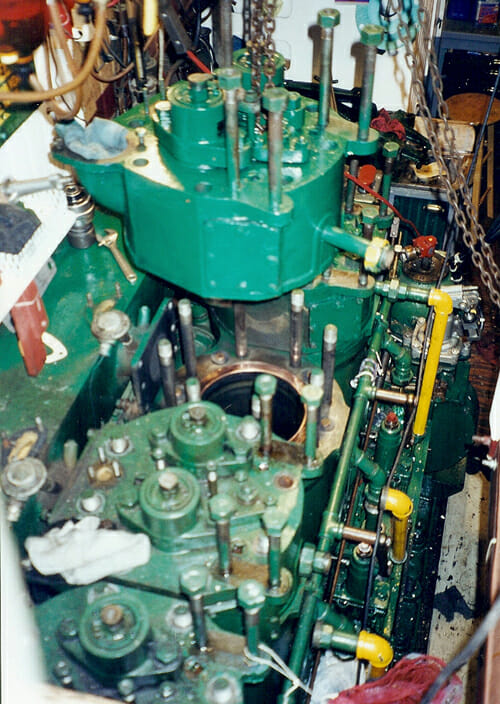

Next I tackle the engine–it’s now 2000–a millineum project. All the heads come off and three are found to have cracks from overheating. Two can be pinned and a third is replaced. I own three of these engines which sit in a container down somewhere in Kent. Each head weighs about 450 lbs.

Here’s a top down view of the pistons–this is a 6-R-13 which is a 6 cylinder 13″ stroke (10″ diameter)–each piston is another 340 lbs. The rods that are connected another 300. I have to build a steel I-beam and bolt it on the new roof beams I recently installed and raise each piece at a time and roll them out the door for work in daylight.

Here are two heads on the deck–getting a good scrubbing…..and two heads are better than one! And just when you thought you were done……

We continue to haul out every two or three years–second time in Everett, third in Port Townsend–shown here where we put in another dozen planks–a total of 60 over the years were replaced. Remember a spiled plank 3″ thick and 25 feet long probably costs today about $750.00 just for the wood and another $5K to install it. Multiply that by 60 and you will probably feel my pain. In all this restoration costs well over $500,000; probably closer to $750,000 but I quit counting long ago.

To be continued at the whim of the captain…. Yaaaaaarrr!